Calculator and weighing integrator TMX110

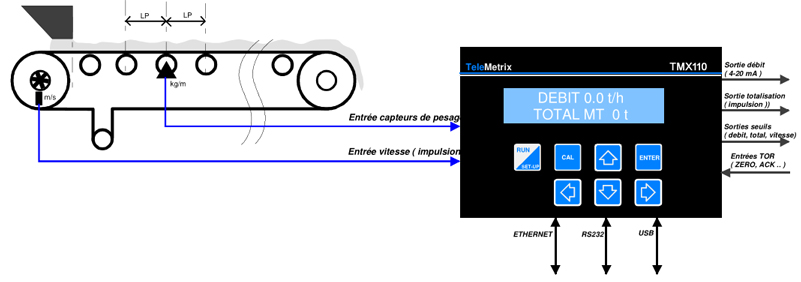

The TMX110 ECUs are dedicated to dynamic or static industrial weighing applications.

Coupled with a weight and speed sensor, they are designed for the uninterrupted weighing of a load on a conveyor belt or roller conveyor, Archimedes’ screw.

The new series of TMX110 calculators is a valuable aid in managing your bulk products production.

Applications:

Determining the flow and total quantity of mineral or food products. Flow regulation, alimentation of crushers, driers. Continuous flow control of primary and secondary crushers in the quarry.

The new series of TMX110 calculators is a valuable aid in managing your bulk products production.

Version: Dynamic weighing

- Simple and clear display of values: flow, total weight, speed, anomaly …

- Multi-language display : French, English, Dutch, German (other languages possible)

- Self-calibration weighing and speed and/or by material test.

- Self-diagnosis of all parts the scale is made from: Weighing and speed sensors, E/S …

- Taring automatic

- Powerful weighing algorithm allowing precise weighing even in the case of a large variation in flow

- Totalizing pulse output

- 3 levels of totalizer

- Pulse speed input, power contact, analog or modbus

Advanced features:

- Loading stop according to a belt management order

- Flow regulation

- Continuous dosing according to a proportional guideline

- Optimized speed

Version: Static weighing

- Simple and clear display of values: GROSS – TARE – NET in kg or tons

- Self-calibration: just enter the features and the number of sensors

- Taring automatic over the whole range

- Analog output 4-20 mA for tank or silo weighing

Additional features:

- Loading stop at a predeterminated weight threshold

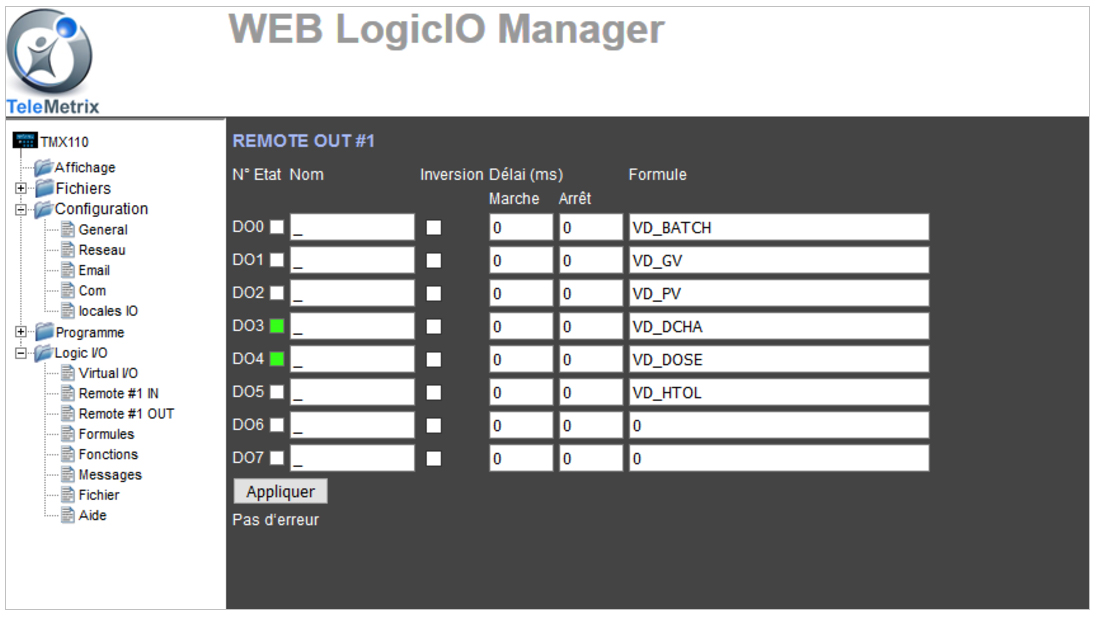

Version: Batch dosing with integrated LogicIO PLC

- Simple and clear display of values: BRUT – TARE – NET in kg or tons

- Large and low-speed dosage on TOR contact and analog output for the control of a speed dimmer or vibrator

- 99 programmable formulas with fall correction and tolerance management.

- ‘LogicIO’ built-in programmable automaton for managing the cycle upstream and downstream of a bagger

LogicIO features:

The TMX110 indicator incorporates a dosing cycle directly into its weighing program to make the dosage faster and more accurate. Depending on the programming the user can adapt the cycle: TARING,tolerance control, LOADING-UNLOADING. Secondary dosing functions such as departure authorizations, draining or evacuation control are managed in the LogicIO program module built into the TMX110.

LogicIO is fully programmable from the WEB server without any need for specific software.

LogicIO is a software module built into the TMX110 with an automaton function that can be programmed by the installer. The programming of the automaton is done simply through the WEB server of the TMX110 (no need for software installation).

LogicIO controls the local inputs/outputs of the TMX110 (OUT1 & OUT2, IN1 & 2) and also remote outputs by MODBUS TCP such as WAGO or MOXA .

The data exchange between the two modules, essentially binary 0-1, is carried out by system variables. The assignment of variables/system variables to inputs and outputs is left to the user’s choice.

|

Cycle Time |

Programmable from 10 ms to 1 second. |

|

Max number of variables |

512 |

|

System Variables |

64 |

|

MODBUS TCP Remote Outputs |

16 ( 8 Module1 + 8 Module2) |

|

MODBUS TCP Remote Entries |

16 ( 8 Module1 + 8 Module2) |

|

Formulas |

16 |

|

Duties |

16 (Timer, Bistable, Counter … ) |

|

Programmable messages |

16 (Text 20 characters max) |

Version: Weighing Integrator for CFM Impact Plate Flow Meter

- Simple and clear display of values: Flow rate, Total weight, Anomaly, etc.

- Self-diagnosis of all the components that make up the flow meter: Load cells, I/O, etc.

- Taring automatic

- Multi-calibration according to the products ( Correction coefficient on the gain )

- Totalizing pulse output

- 3 levels of totalization

Advanced features:

- Loading stop according to a belt management order

- Flow regulation

- Continuous dosing according to a proportional guideline

Version: Flow Controller for PID Belt Feeder

- Simple and clear display of values: Flow rate, Total weight, Speed, Anomaly

- Dual Loop PID Flow Controller

- Remote or local flow direction

- Self-calibration weighing and speed and/or by material test.

- Self-diagnosis of all parts the scale is made from: Weighing and speed sensors, E/S …

- Taring automatic

- Totalizing pulse output

- 3 levels of totalizer

- Pulse speed input, power contact, analog or modbus

Advanced features:

- Simultaneous multi-product mixing

- Optimized speed

Version: Archimedes' Loss-in-Weight Screw Flow Regulator (LWR)

- Simple and clear display of values: Flow rate, Total weight, Setpoint, % control, Cycle anomaly, etc.

- PID regulator double loops on the flow calculated by the weight difference between a predetermined time.

- Flow setpoint input in Local or Remote (analog 4-20 mA or digital)

- Self-calibration of load cells

- Self-diagnosis of all parts the scale is made from: Weighing and speed sensors, E/S …

- Taring automatic

- Powerful weighing algorithm for precise and fast regulation

- 4 analog outputs: Instantaneous flow, Weight / Total weight, Control, Setpoint…

Advanced features:

- Setpoint change with active output preset

- Auto-tunning of the PID controller

Version: Level measurement with CLEVEL strain gauges

Display in Weight and % of level in a silo equipped with type 178 or GZ3 gauges

- Calibration by HIGH/LOW point calibration (no imposed order)

- Self-diagnosis of the assembly: Voltage sensor …

- Analog outputs: 4-20 mA / 0-10 V.

Advanced features:

- Extended sensor input of + – 100.00 mV

- Extended filtering 30mn/1h/24H

Characteristics:

General characteristics

Input load cell:

Low voltage sensor power: 5V

Minimum echelon: 1 Microvolt

Resolution: 300,000 points

Digital and analog filter

Connection of up to 10 load cells (via junction boxes BJ4M, BJ4P, BJ6M, BJ8M, …

Duties:

Blue color LCD display 2 x 20 characters

Intuitive 7-key keyboard

IP65 waterproof front panel (delivered with a removable protective cover)

Multi-language display: French, English, Dutch, German (other languages possible)

Delivered with a library of dedicated programs (downloadable free of charge or on a USB stick), the TMX110 is designed for a very wide range of weighing applications:

- Dynamic weighing: Weighing on continuous or isolated load conveyors, weighing augers

- Static weighing: sensor weighing line, silo weighing, hopper

- Impact Plate Weighing: Specifically designed to work with CFM flow meters

- Circuit Flipper: Single or Double Skip Batch Totalizer

- Level measurement by strain gauges: CLEVEL

- Flow control for stepless weighing

- Flow control by weight loss

- Dosing – bagging with integrated PLC: LogicIO

Communication:

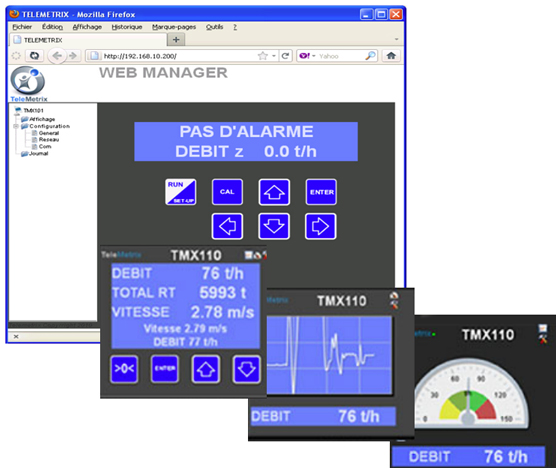

The TMX110 has many interfaces as standard:

- ETHERNET with WEB SERVER, FTP, TELNET, SSH and ioscan-compatible MODBUS-TCP protocol.

- USB: saving parameters and calibration on memory stick

- 2 programmable digital inputs

- 2 outputs on 48V/4A relay

- 1 analog output 4-20mA / 0-10V

- 1 analog input for control setpoint.

- RS232 link for printer or repeater

- Timestamp

The traditional 4-20 mA Inputs/Outputs/Relays ensure perfect compatibility with most existing or future switchovers and automations.

Feeding:

- Power supply 24VDC 0.4 A or 240VAC 15VA

Benefits:

- Numerous interfaces as standard ( RS232 / USB/ 4-20mA … )

- Comes with an app library.

- Embedded WEB server.

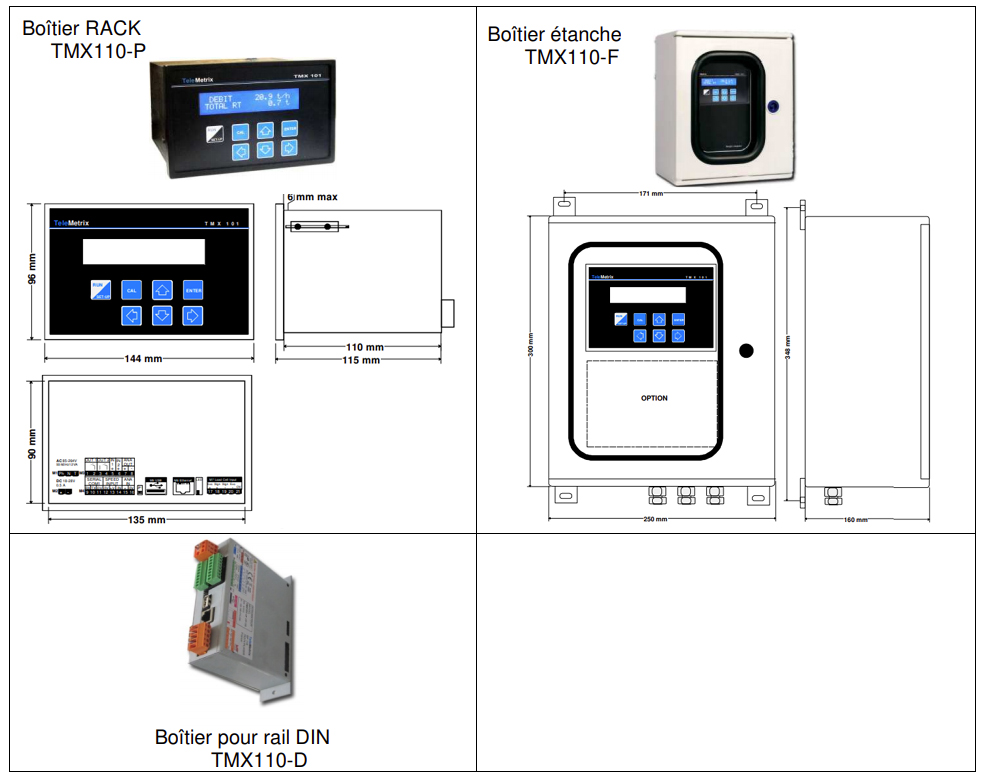

Size